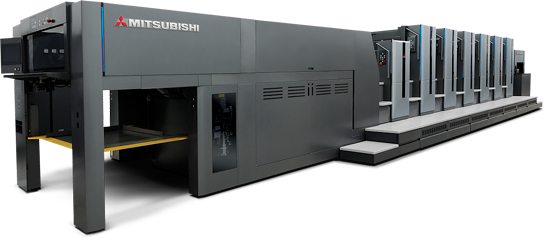

RYOBI MHI V3000 LS

The V3000LS features cutting-edge technologies on a rigid, proven base press model employing a seven o’clock cylinder arrangement with double-diameter impression and transfer cylinders. The press accommodates a wide range of optional features, including coating units and drying equipment, to meet high-value-added printing needs.

- Feeder & delivery sheet size preset system

- Remote-controlled positioning of separator, side guide, feeder board brush/rollers, vacuum slowdown

wheel (positioning and air flow) and side joggers

- Vacuum feeder tapes

- Pneumatic side-lay

- Sheet feeding speed slowdown device

- Double sheet detectors

- Mechanical, photoelectric and ultrasonic

- High precision ink keys

- Active stabilized inking system

- High-speed printing startup system

- Sheet trend monitor and sheet alignment device

- Three-way remote-controlled register

- Circumferential, lateral and cocking

- Multi-mode dampening system

- AD-mode, semi-AD mode and ITD mode

- Automatic plate changing system

- Automatic preset inking

- Impression pressure presetting system

- Intelligent Press Control III (IPC III)